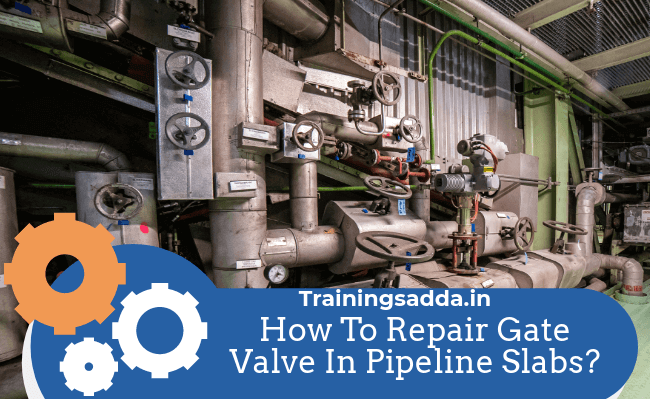

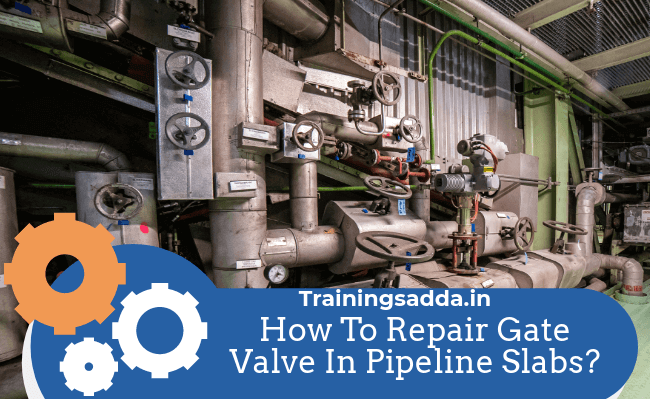

How To Repair Gate Valve In Pipeline Slabs?

US oil generation has levitated to a certain extent that was unbeatable and was never seen in the past. A massive production level increase to 10 million barrels a day was recorded in last November since 1948. Few reports even claimed that the estimated production could even outreach till 12 million barrels a day by the closure of 2019.

Read more: 10 Top Gate Valve Manufacturers to Consider in 2019

On the other hand, the growth benefit was seen in the oil and pipeline companies; few challenges were popping up on the other side. To be specific, there were various pumping stations accompanied by pipelines which were not in regular operation, due to which faulty parts.

Slab gate valves coated with nickel-plated stems with the gates are usually found at pumping stations and the attached pipelines. These valves were really common 25 years ago. It changed when authorities noticed the nickel-plating falling off issues or the seal breakage lead to continuous valve leak.

This issue can be entirely supervised under any good valve factory or organization. They have come up with advanced ideas to resolve the matter and benefit the client by saving 60% on repairing cost in a year.

Learn more: Important Tips When finding a Good Cable Manufacturer Online

Table of Contents

An Outlook Idea Of Slab Gate Valves

Usually, a slab gate valves manufacturer will design it with a single gate component, which can be raised and lowered between two seated rings and are majorly used for transferring petroleum products. For example- crude oil, gasoline, and diesel. Few are also gas service components. These can be used widely in pumping stations according to the length of the pipelines. The valves are either found buried under the ground or above the surface.

Benefits Of Slab Gate Valves

Like any gate valves, the prime benefit of a slab gate valve is to act as a mediator for transferring fluid components like air, gas, fuel, lubricant, etc. The other benefits include:

- Pressure fall can by using these valves be less or even controllable.

- Mostly the valves have bi-facial or bi-directional feature through which liquid transfer is secure.

- Gate valves can withstand high temperatures and pressures well.

Disadvantages of Slab Gate Valves

These valves also come with a few disadvantages:

- At times, slow in the process while operating. The opening and closing technique of the valves is a time-consuming process.

- Often vibration and annoying noise can be experienced if the valves are partially opening.

- Repairing of the valves can involve a lot of time and money.

Significant Problems Related To The Valves

Around 95% of the slab gates in the production industry are comprised of nickel coating. When nickel was used for the first time, it was thought that nickel could be a strong survivor for a long time. Unfortunately, it was with growing time, which proved the assumption to be false. After a prolonged period of service, nickel coating started falling off, which again caused the upper plate and lower bonnet to leak quickly.

Read more: The Internet of Textiles: What’s Here and What’s Coming

Things To Remember Before Repairing A Valve

Eventually, any gate valve stops working after some time due to leakage, either internal or external. A gate valve can only work if a wedge-shaped piece of brass material is inserted or deeply forced in the slot. When the system is full of toxic things, it won’t close or may partially close.

- To begin with, the repair is ensured that the water is fully drained out. You can open the valve and then entirely shut it off.

- Taking off the screws from the valve can be a bit challenging as pipelines can get strained. It is because of the compact size of the entire body of the valve.

Critical Observation

While working on this process of rectification, the technicians have found the right conditions of the valve body, slab, and seating arrangements. Even they observed the functionality of the valve service was working excellent. All of the issues were related to the nickel body draining from the stem, valve body, and upper and lower bonnet system.

Learn more: Things You Should Know Before Buying Ethernet Cables

So, a replacement of the entire stem and the sealing system was required. Furthermore, as the whole valve system was constructed underground, so the clients wanted a repair outright on the spot instead of any digging procedure.

Solution Provided

The company has a valve team that generally works with an advanced innovative mind on the nickel plating destruction problem. The conclusion was drawn that while any replacement of nickel plating or coating, they should provide more focus on the valve.

Valve breaking or leaking during replacement could have a challenge during the replacement process. Technicians have renovated the upper plate of the stem by using an advanced hefty material which can survive long and designed it using new tools.

Changes That Were Done

Restoration of Nickel Plating

Stainless steel is a robust, breakdown proof material. Nickel plated material, on the other hand, is not that corrosion resistant. 17-4 stainless steel is installed by replacing the nickel because of the high resistance power; there wasn’t any plating required anymore.

Bonnet Restructure

Scraps can easily flow through crude oil, for example, dirt, debris, sands, etc. and cause a blockage around the seal opening. Four energized seals were incorporated in the bonnet system, and the top plating was also changed. The three-strong seals were there as backup support for one seal’s illegal operation. To make the pumping system workflow smoothly, these four seals were installed.

Grease Fitting Bonnet

Specifically, every valve bonnet contains a single hole which has a greasy texture. The design was made in such a way that if any leakage happens, excess grease can be injected inside to stop the leakage from the fitting. Opposite to the bonnet, there was a hole which has been drilled in. This hole allows the smooth movement of grease from one end to another without any blockage. A complete coverage assurance is guaranteed by this whole procedure of drilling holes.

Learn more: Why you should learn MQTT in 2019?

Conclusion:

To get the reassurance of the repair result, make sure to check the operation of the gate valves thoroughly through the pipelines. For the smooth working of a valve requires proper lubrication from time to time. During different seasons especially in winter, the frequency of lubrication should be done more. In this way, you can maintain the gate valves properly to save repair or replacement costs.

Comments

0 comments